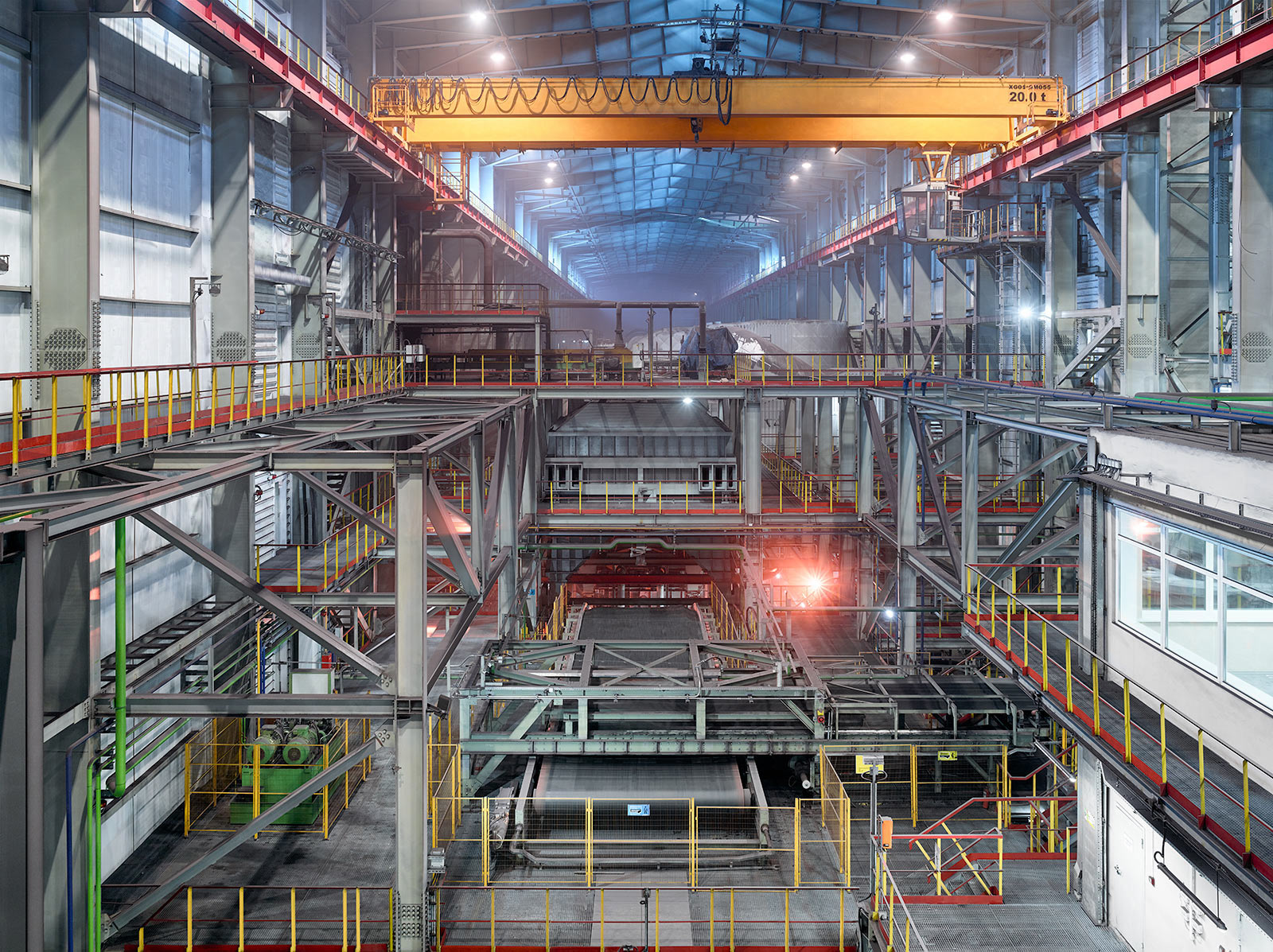

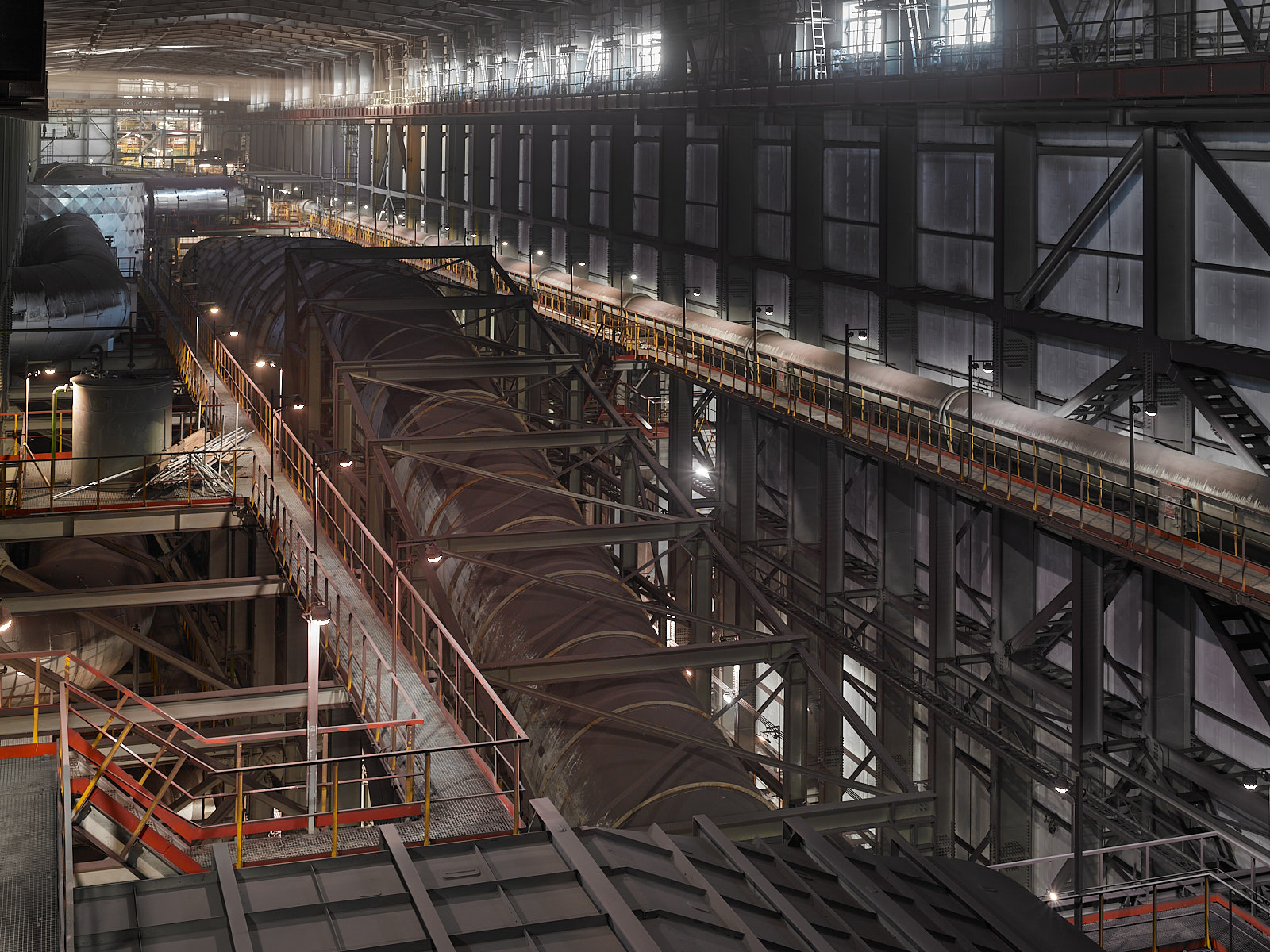

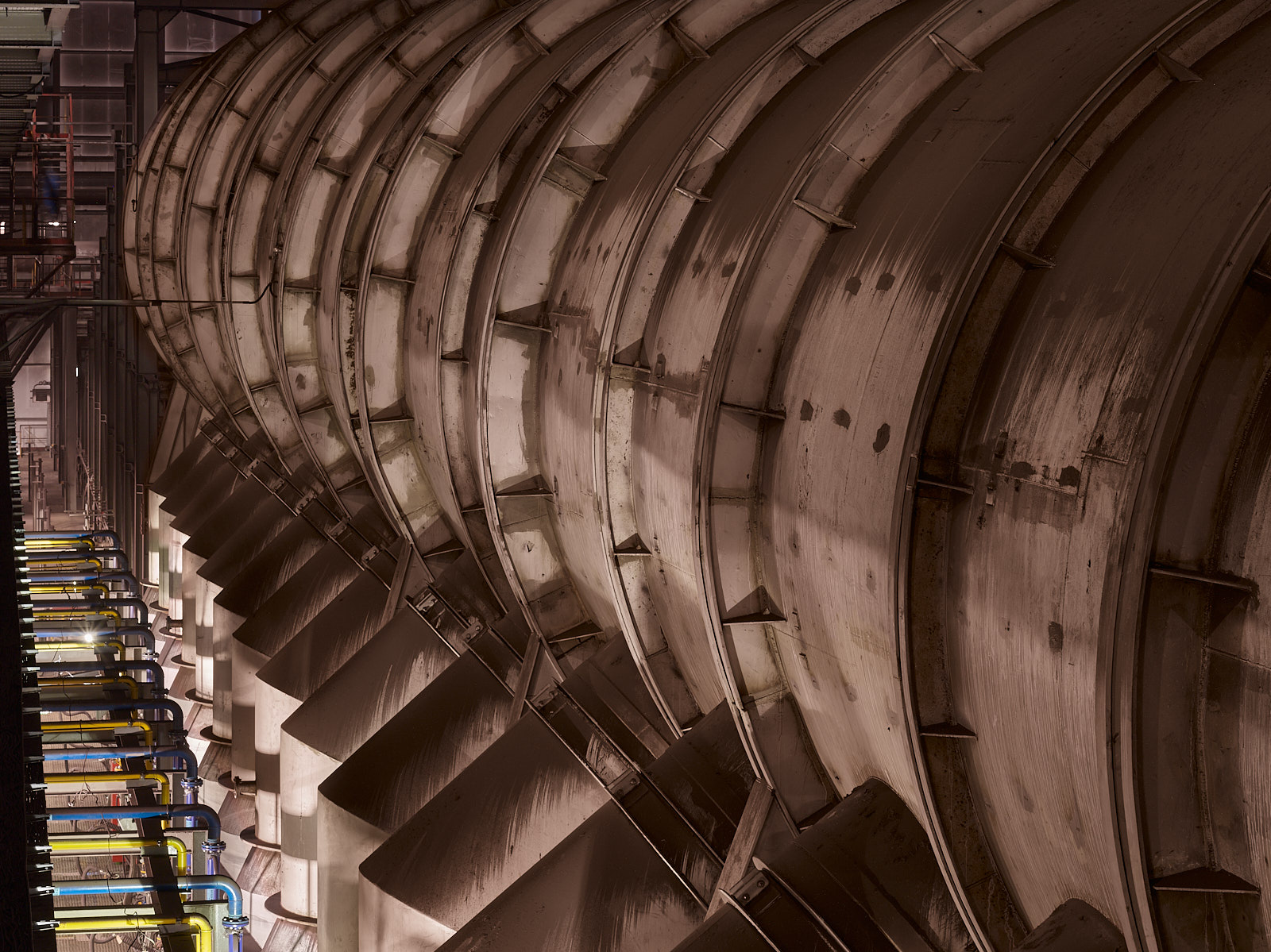

Iron Ore Pelletization

This high-tech facility took two years to build. The active phase of the project and required a total investment of around $680 million (34 billion rubles). The best available technology and equipment was selected during the design phase. The largest kiln in Europe ensures the plant’s high performance at 780 tonnes of pellets produced per hour. The Stoilensky plant is the first in the Russian metals and mining industry to use high-efficiency hyperbaric filters to remove fluid during the processing of ore. The concept behind the design of the pelletizing plant is that of an environmentally friendly, waste-free facility, in which waste charge material and captured dust are introduced back into production. A high efficiency dedusting system captures up to 98% of emissions. The plant’s labour productivity of 22.9 tonnes per person is the highest among its peers in Russia and the CIS.

Client: Outotec

Related Project Work